Usage of corrugated steel fibers

- Share

- Issue Time

- Apr 17,2019

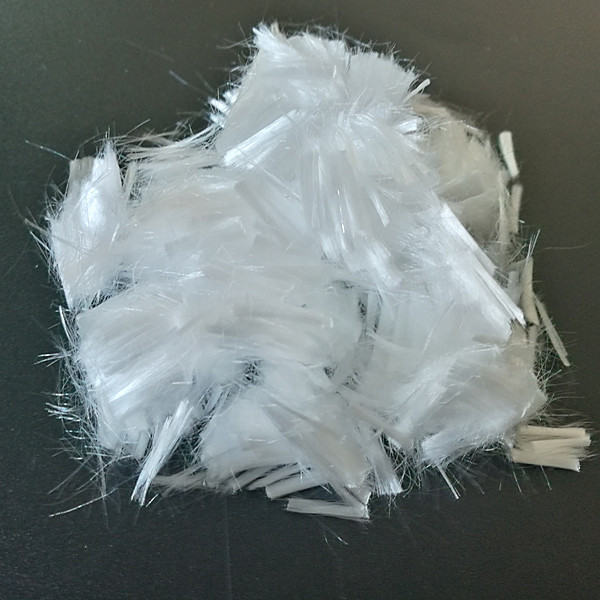

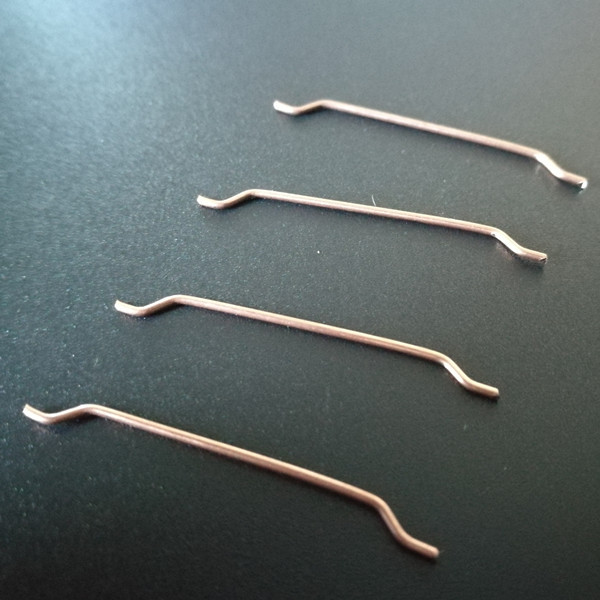

The basic shape of corrugated steel fibers is similar to that of shear products, but the tensile strength of single fibers has been greatly improved, reaching more than 1100 Mpa, which is suitable for key projects and large areas of concrete crack resistance parts. Today, the corrugated steel fiber manufacturer, Longyu Steel Fiber, Suzhou, has a brief talk with you about the use of corrugated steel fibers.

1. Doping amount: 0.5-2% volume, that is, 30-120 kg/m3 (or according to the actual situation).

2. Material requirements: steel fiber reinforced concrete shall not use sea water or sea sand, and chloride salt shall be strictly prohibited.

3. Mixing: The workability of steel fiber reinforced concrete can be determined by referring to the slump required for ordinary concrete in similar projects, and the mixing time can be appropriately prolonged to ensure the uniform dispersion of steel fiber.

4. Maintenance: The construction and maintenance technology of concrete with fibers is identical to that of concrete without fibers.

5. Safety in use: Proper attention should be paid to labor protection to prevent stabbing and splashing of eyes;

HOT SALE HARVEST Melt Extract Steel Fiber

fiber can improve the reinforcement of mortar or concrete performance effectively to make them strong and protect the projects

High carbon steel wire, low carbon steel wire, galvanized wire, stainless steel wire and other metal wires

higher strength and toughness.It has better high-temperature strength and high-temperature corrosive character.